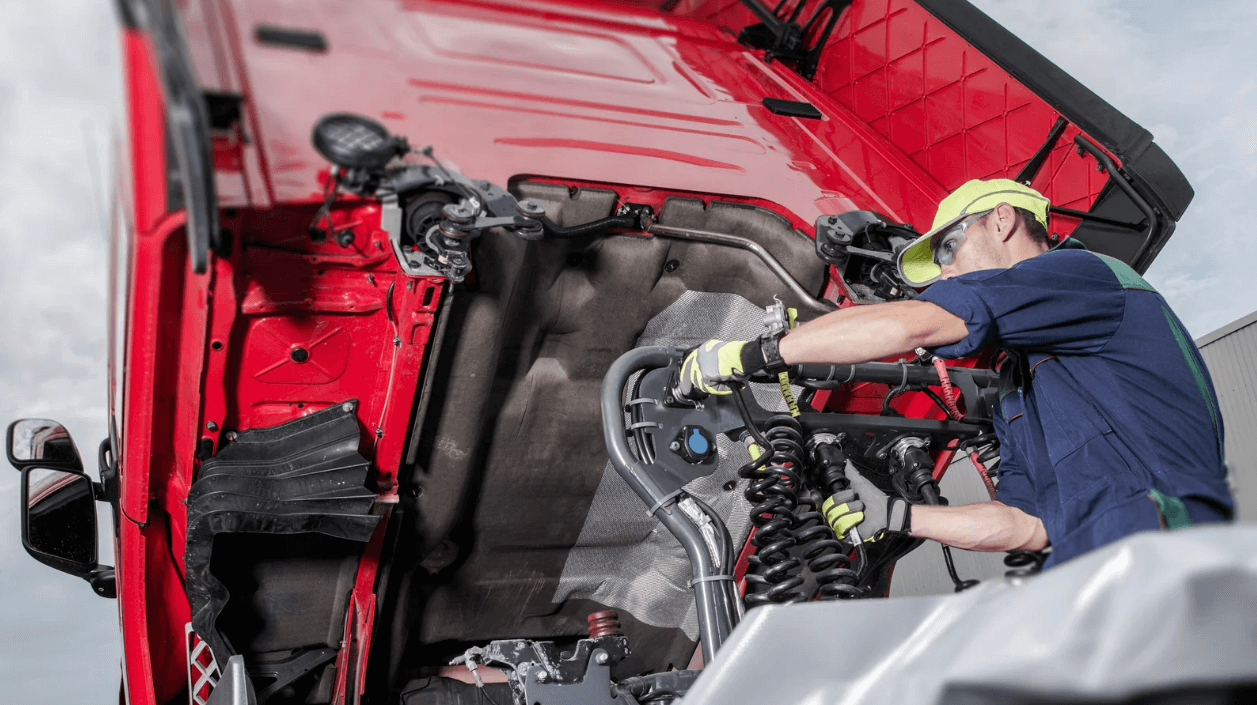

As a truck driver or fleet owner, keeping your vehicles in top condition is crucial for safety, efficiency, and profitability. Weather conditions can have a significant impact on your trucks’ performance and neglecting seasonal maintenance can lead to unexpected breakdowns, costly repairs, and downtime. By proactively addressing specific maintenance tasks tailored to each season, you can minimize weather-induced issues and keep your fleet running smoothly year-round.

The Importance of Seasonal Maintenance

Each season presents unique challenges for heavy-duty vehicles. Temperature fluctuations, precipitation, and road conditions can affect various components of your trucks. Seasonal maintenance ensures that your vehicles are prepared to handle these changes, reducing the risk of accidents and mechanical failures.

Spring Maintenance: Recovering from Winter’s Wear and Tear

Winter conditions can be harsh on your trucks. As the weather warms up, it’s essential to address any damage caused by cold temperatures, snow and road salt.

1. Inspect for Corrosion and Rust

- Undercarriage Check: Salt and chemicals used on icy roads can corrode the undercarriage.

- Action: Clean the undercarriage thoroughly and apply anti-corrosion treatments if necessary.

2. Tire Inspection and Rotation

- Tread Wear: Cold weather can cause uneven tire wear.

- Action: Check tread depth, look for cracks or damage and rotate or replace tires as needed.

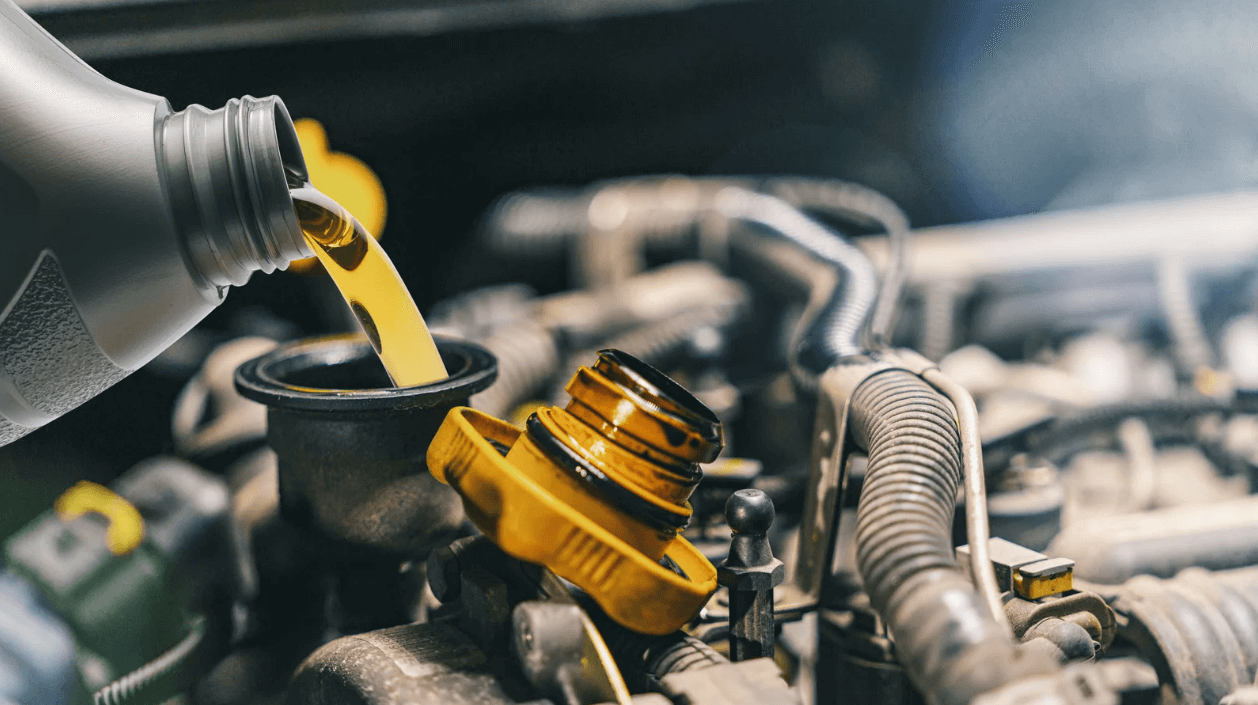

3. Fluid Levels and Quality

- Oil and Filters: Winter can thicken oil and clog filters.

- Action: Change oil and filters to ensure proper engine lubrication.

- Coolant System: Check for leaks and ensure coolant levels are adequate.

4. Air Conditioning System Check

- Functionality Test: Ensure the AC system is working before the hot weather arrives.

- Action: Inspect refrigerant levels and replace cabin air filters.

Summer Maintenance: Combating Heat and High Temperatures

High temperatures can strain your truck’s systems. Preparing for the heat can prevent overheating and other temperature-related issues.

1. Cooling System Inspection

- Radiator and Hoses: Heat can cause hoses to crack and radiators to fail.

- Action: Inspect for leaks, clean the radiator, and replace worn hoses.

2. Tire Pressure Adjustments

- Pressure Changes: Heat increases tire pressure, risking blowouts.

- Action: Regularly check and adjust tire pressure according to manufacturer recommendations.

3. Battery Performance

- Heat Damage: Batteries can overheat, reducing their lifespan.

- Action: Test battery charge, clean terminals and replace, if necessary.

4. Brake System Evaluation

- Increased Use: Hot weather can affect brake performance.

- Action: Inspect brake pads, rotors and fluid levels; replace worn components.

Fall Maintenance: Preparing for Colder Weather

As temperatures begin to drop, it’s time to get your trucks ready for the challenges of winter.

1. Heater and Defroster Checks

- Functionality Test: Ensure the heating system is operational for driver comfort and safety.

- Action: Inspect and service heaters and defrosters.

2. Windshield Wipers and Washer Fluid

- Visibility Matters: Wipers may have worn down over summer.

- Action: Replace wiper blades and fill washer fluid with a winter formula to prevent freezing.

3. Lighting System Inspection

- Shorter Days: With less daylight, functioning lights are crucial.

- Action: Check headlights, taillights, turn signals and marker lights; replace any burnt-out bulbs.

4. Tire Assessment

- Traction Needs: Prepare for wet and slippery roads.

- Action: Evaluate tread depth and consider switching to all-weather or winter tires.

Winter Maintenance: Battling Cold and Icy Conditions

Winter weather poses significant risks, but thorough preparation can mitigate many issues.

1. Antifreeze Levels and Quality

- Engine Protection: Antifreeze prevents the engine from freezing and overheating.

- Action: Test antifreeze strength and top off or replace as needed.

2. Cold Weather Tires and Chains

- Enhanced Traction: Snow and ice demand better grip.

- Action: Install winter tires and carry chains where required by law.

3. Battery Care

- Cold Cranking Amps (CCA): Batteries lose power in cold temperatures.

- Action: Test the battery’s CCA, clean connections and replace older batteries proactively.

4. Fuel System Maintenance

- Prevent Gelled Fuel: Diesel can gel in low temperatures.

- Action: Use anti-gel additives and keep fuel tanks full to prevent condensation.

5. Air Brake System Attention

- Moisture Risks: Condensation can freeze in air lines.

- Action: Drain air tanks daily and use air system antifreeze, if necessary.

Year-Round Best Practices

Regular Inspections

- Pre-Trip Checks: Conduct thorough inspections before every trip.

- Professional Maintenance: Schedule regular maintenance with qualified technicians.

Stay Informed About Weather Conditions

- Weather Monitoring: Use weather apps and services to stay ahead of changing conditions.

- Route Planning: Adjust routes to avoid severe weather when possible.

Driver Training

- Educate Drivers: Ensure drivers are trained to handle weather-related challenges and understand the importance of reporting maintenance issues promptly.

Conclusion: The Value of Proactive Maintenance

Seasonal maintenance is more than a routine task—it’s a critical component of safe and efficient trucking operations. By addressing specific maintenance needs each season, you can prevent weather-induced breakdowns, extend the lifespan of your vehicles, and ensure the safety of your drivers and cargo.

Stay ahead of the weather and keep your fleet on the road by making seasonal maintenance a priority. Your proactive approach today will pay off in reliability and peace of mind throughout the year.

Write a comment: